Race RZR

Power, suspension, traction, safety and more!

Well, it’s been almost 2 months since Stage 1, and we’ve accomplished quite a bit on the RZR. But, before we jump into everything we’ve done, we’ve taken a slightly different direction with the Race RZR Buildup than we originally planned. It’s easy to go all out when building a race vehicle when a lot of the products are donated, but the reality is that most people racing are putting a lot of hard-earned money into their race UTVs. And, in case you haven’t checked, a lot of race UTVs have morphed into $30-$50K vehicles, which is still cheaper than a lot of racing, but still out of the reach of most folks. So, in an effort to bring UTV racing more mainstream, we’ve decided to build an extremely functional Race RZR on a limited budget. This doesn’t mean we’re going to skimp on the required items to be race legal, but rather will try to keep the expenses to a minimum where it’s feasible.

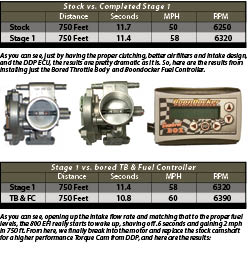

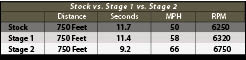

With that being said, we obviously want to be competitive, so there are still some motor mods that we wanted to complete that will make up for our driving ability. Keep in mind, though, this is probably our competitive nature coming out, but these motor mods are definitely not a requirement for the average family to race. But, if you want one of the fastest and reliable RZRs out there, Dirty Dawg Performance has come through again with a great combination of power and reliability with their Bored RZR Throttle Body, Boondocker Fuel Controller, and the DDP Torque Cam for the Polaris RZR. Here’s a chart of the results from stock through Stage 1 in case you missed it:

Wow! With the above listed modifications, we’ve taken off 2.5 seconds and gained 16 mph in just 750 ft. Please note, for those looking at your factory speedometer, the speeds indicated in these tests were performed with a highly calibrated radar gun. The stock speedometer runs 4-5 mph fast. Our measured top speed was 68 MPH with the completion of Stage 2. From here, the last of our engine mods are going to be a DDP header and mid-pipe and a ported and polished H.O. head.

But, just FYI, in our recent Soboba Grand Prix race, there wasn’t a faster RZR in the field of 42 UTVs just with Stage 2 completed. Now, if only my driving skills were up to par with the power and speed of the RZR!

Because of the short notice to get the Polaris RZR prepped for the Soboba GP, we decided to reinforce the RZR stock role cage rather than doing a full replacement cage. To do so, we bought a 20’ stick of 1.5”x.095 and a half stick of 1”x.120. We ended up using a few feet shy of the 20’ to weld in the necessary supports to make the cage a lot stronger than stock. In addition to the 1.5” tubing, we used a short piece of the 1” tubing to add the finishing gusset on the side in the event of a front end-over-end rollover. This brings me to the thought process we put into the extra gussets for the cage. What we tried to do is mimic where the forces of impact transfer to the frame of the RZR, and if there’s a weak spot, add the necessary tubing to eliminate the weakness. From this picture, if you can envision a side rollover, the force is transferred across the top tube and down the opposite angled tube that we added to the base of the roll cage. And, if you view the cage from the side, if a frontal impact occurs, we added the 1.5” tube across the top, then the 1” gusset in the back to prevent both the front

Because of the short notice to get the Polaris RZR prepped for the Soboba GP, we decided to reinforce the RZR stock role cage rather than doing a full replacement cage. To do so, we bought a 20’ stick of 1.5”x.095 and a half stick of 1”x.120. We ended up using a few feet shy of the 20’ to weld in the necessary supports to make the cage a lot stronger than stock. In addition to the 1.5” tubing, we used a short piece of the 1” tubing to add the finishing gusset on the side in the event of a front end-over-end rollover. This brings me to the thought process we put into the extra gussets for the cage. What we tried to do is mimic where the forces of impact transfer to the frame of the RZR, and if there’s a weak spot, add the necessary tubing to eliminate the weakness. From this picture, if you can envision a side rollover, the force is transferred across the top tube and down the opposite angled tube that we added to the base of the roll cage. And, if you view the cage from the side, if a frontal impact occurs, we added the 1.5” tube across the top, then the 1” gusset in the back to prevent both the front  and rear junctions from collapsing. In the front, we did the opposite of the rear V in the event of a side flop. This brings me to another point in reference to these cage reinforcements. Having the strongest cage in the world isn’t going to do a thing if you don’t have the proper restraints to hold the drivers and passengers in properly. We chose 3” 5-point harnesses to make sure we stay put in the event of a wreck. Obviously, these items are required by the race coordinators, but don’t forget to keep this in mind when riding recreationally, as well. I can’t tell you enough how important a good set of harnesses for RZR, a good helmet, and a good cage are to living through a light rollover in one of these UTV’s. It only takes once for a

and rear junctions from collapsing. In the front, we did the opposite of the rear V in the event of a side flop. This brings me to another point in reference to these cage reinforcements. Having the strongest cage in the world isn’t going to do a thing if you don’t have the proper restraints to hold the drivers and passengers in properly. We chose 3” 5-point harnesses to make sure we stay put in the event of a wreck. Obviously, these items are required by the race coordinators, but don’t forget to keep this in mind when riding recreationally, as well. I can’t tell you enough how important a good set of harnesses for RZR, a good helmet, and a good cage are to living through a light rollover in one of these UTV’s. It only takes once for a  freak accident to occur, that’s for sure. I’m not saying they’re unsafe, just respect the possible things that can go wrong. Just ask someone that has had someone hurt in one!

freak accident to occur, that’s for sure. I’m not saying they’re unsafe, just respect the possible things that can go wrong. Just ask someone that has had someone hurt in one!

So, enough ranting about safety, and we’ll move on to how we reinforced the RZR frame. Because we were limited on time to complete the RZR for the race, we only had time to sleeve the various points on the frame that have a tremendous amount of force on them. If you look at the rear of the Race RZR, you’ll see that we used 1”x.120 wall tubing to sleeve the insides of the stock frame. There’s two upper, two lower in the center main frame, and one at the end of the bottom A-arms. In addition to the rear, we removed the center console and slid pieces of the same tubing inside the front frame tubes and welded those, as well. That’s all we had time to do, and if you read the Soboba GP race article, you’ll see what we discovered worked great and what needs a little more reinforcement.

From here, it was time to put some real tires and wheels on the RZR that would withstand the punishment a race vehicle goes through. Since we just performed our RZR tire test, we could at least base our decision on some hard testing. But, it wasn’t an easy decision, so we turned to some of the best racing teams to get their opinions, as well. After reviewing all the facts, we made the choice to run 25”x8” wide Goodyear MTRs at all 4 corners. Why, you ask? Well, the MTRs are the lightest tire we tested, performed in the top 3 in most of the categories, and by running a front tire in the rear too, we shaved 7-13 lbs/tire in the rear and a minimum of 4lbs up front. Saving this weight really helps acceleration out of corners, not to mention overall better handling on these UTV’s. To match the lightweight and durable performance of the Goodyear MTR’s we decided that Tracy Rossman from SRT Racelocks had the perfect beadlock RZR wheel for our racing application. The SRT Racelock wheel we’re using is a combination of a Douglas wheel and Tracy’s outer beadlock. But, it doesn’t stop there. SRT Racelocks modifies the stock Douglass wheel to make its overall weight less than 10.5 lbs, which is unheard of for a beadlock wheel.

From here, we’ll cover some of the things you might easily overlook when building a race UTV. To start, visibility out the front and rear is top priority, so I made sure I had plenty of tear offs for my goggles. We also installed an Xtreme Machine & Fabrication Billet Panoramic Center Mirror and two Machine Trix RZR Billet Side Mirrors. At first thought, why would I care what or who was coming up behind me. All I had planned on being worried about is passing the people in front me, and this is generally true. But, at the same time, if there’s someone behind you that’s obviously faster than you, the right thing to do is let them by, apparently. Both sets of mirrors install in a matter of minutes, and the only recommendation I have is to install the side mirrors so during an impact they rotate on the roll cage rather than break off. Trust me, I didn’t necessarily do this on purpose, but I can attest to Machine Trix Mirror’s strength…twice!

Last, but not least, we did some final testing the Friday before the Soboba GP with Steve Chase @ Makin’ Trax Suspension to make sure the Polaris RZR was dialed in perfectly for the race. What was funny was that after spending almost a full day with the RZR to make sure they were dialed in perfectly, we essentially ended up right where we were before we tried some new ideas. What’s amazing is that these AFCO MT2 shocks work so well with the stock A-arms. I can’t even imagine what this Razor is going to handle like with the RZR long-travel kit on.

So, for more information on our first completed race in the Polaris RZR, read the Soboba GP article in this issue. For the next issue, the plan is to have the long-travel installed, additional frame gusseting, fuel cell, doors, and lots more in preparation for the upcoming races.